- Home

- About Us

-

- Offer Documents

- Audiovisual AV for IPO

- Group Companies

-

- MOA & AOA

- Business Details

- Terms and Conditions of Appointment of Independent Directors

- Composition of Various Committees

- Code of Conduct of BOD and SMP

- Details of Establishment of Vigil Mechanism / Whistle Blower policy

- Criteria of Making Payments to Non-executive Directors

- Policy On Dealing With Related Party Transactions

- Policy For Determining ‘Material’ Subsidiaries

- Familiarization Programmes Imparted to Independent Directors

- Email Address For Grievance Redressal

- Shareholding Pattern

- Disclosure of The Policy For Determination of Materiality of Events or Information

- Dividend Distribution Policy

- Annual Returns

- Other Disclosures

- Financials and Reports

- Investor Contact

- Policies

- Announcement

- Corporate Governance

- Contact Us

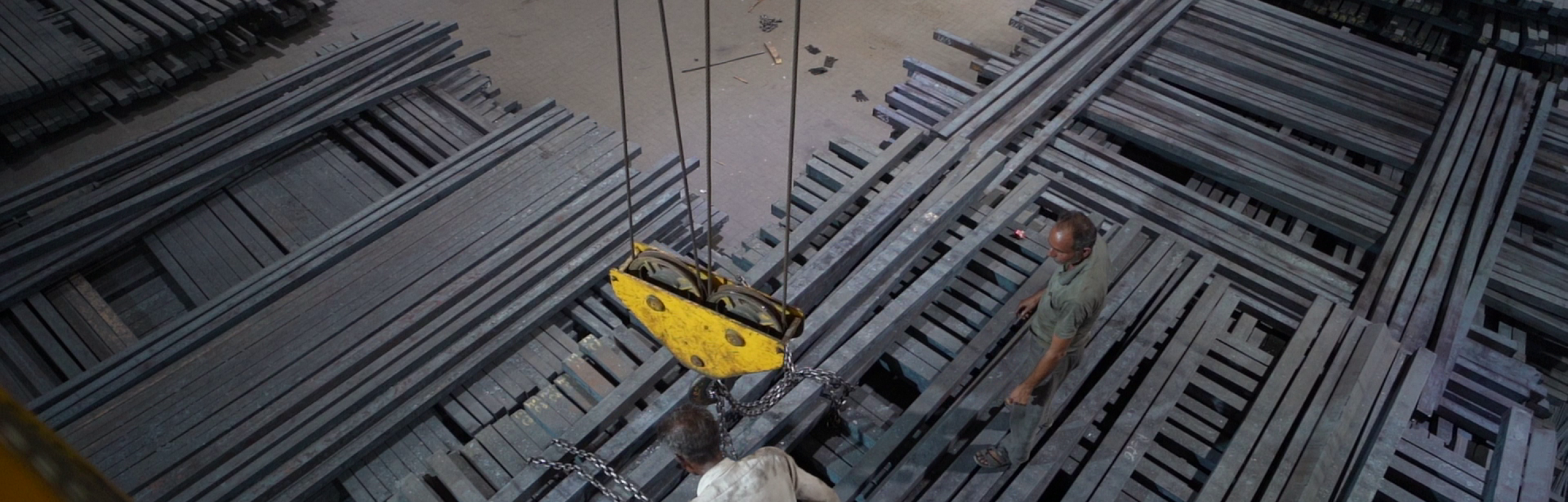

Infrastructure

We manufacture our TMT Bars at our manufacturing facility in Bhayla Village near Ahmedabad in Gujarat, India. Our billet manufacturing will be at the same facility after our backward integration is complete.

In Fiscal 2025, we are diversifying our production to include pipe manufacturing. We have entered a factory lease agreement, dated June 4, 2024, under which we are leasing a facility in Bhavnagar, Gujarat with an approximate installed capacity of 5,500 MT of pipe per month. We expect to begin producing pipe by July 2024.

TMT Bar Production

The key features of our TMT Bars plant include

- Coal Oxy automation to maintain proper flow of oxygen for optimum consumption of coal;

- Oil lubrication system at plant eliminating use of grease for better life cycle and lower breakdown

- Automatic flying shearing, automatic bundling machine, bending machine and cooling bed with layer shifting for better handling

- Use of tensile metal rolls for better shine, perfect size and higher roll life

- Appointed SKF for supply, record maintenance, removal, fixing of all the bearing of the plant

Billets Production - Backward Integration

In accordance with our backward integration project, we will manufacture billets for our TMT Bar production. We are installing a thirty-ton induction furnace with installed capacity of 216,000 MT per annum. The production of billets will be for our own captive consumption to manufacture TMT Bars. The length of the billets can be customized as per the specification of TMT bars to be manufactured.

Key features of our billets unit include

- Both our billets unit and TMT Bar unit will be operated and controlled through unified control panel at single location.

- Cast billets will directly go into rolling which is the first stage of TMT Bar production. This will eliminate the reheating of billets, thereby burning loss will be saved.

- Our consumption of coal will be substantially reduced, and scrap melting will be done through the electric induction furnace which was installed in Fiscal 2024. Accordingly, our current price fluctuation risk in coal sourcing will be eliminated.

Raw Materials, Suppliers and Utilities

Our major raw materials for our manufacturing processes a mild steel scrap, sponge iron and coal. Prior to our backward integration project, our primary raw material for our TMT Bars was iron billets, which we primarily sourced locally in Gujarat.

Our business is significantly dependent on our supply chain management. We have strong supply chain relationships in Gujarat and certain other states. In Fiscal 2024, 63.89% of our raw material purchases were from suppliers in Gujarat. Purchasing locally saves us in transportation costs and time of delivery.

The table below sets forth our cost of materials consumed for periods indicated.

| Particulars | Fiscal 2024 | Fiscal 2023 | Fiscal 2022 | |||

|---|---|---|---|---|---|---|

| ₹ lacs | % of revenue from operations | ₹ lacs | % of revenue from operations | ₹ lacs | % of revenue from operations | |

| Costs of materials consumed | 75,023.48 | 85.94 | 84,699.73 | 96.03 | 37,027.17 | 75.00 |

The table below sets forth cost of materials purchased from our top supplier and top ten suppliers for the periods indicated.

| Suppliers | Fiscal 2024 | Fiscal 2023 | Fiscal 2022 | |||

|---|---|---|---|---|---|---|

| ₹ lacs | % costs of materials | ₹ lacs | % costs of materials | ₹ lacs | % costs of materials | |

| Largest Supplier | 6,672.07 | 8.63% | 9,493.50 | 11.08% | 9,909.42 | 20.48% |

| Top 10 Suppliers | 38,566.55 | 49.88% | 49,209.30 | 57.43% | 32,121.35 | 66.40% |

The table below sets forth state-wise percentage break up of our raw material purchases for the periods indicated.

| State | Fiscal 2024 | Fiscal 2023 | Fiscal 2022 |

|---|---|---|---|

| Gujarat | 63.89% | 77.65% | 93.16% |

| Chhattisgarh | 11.36% | 3.55% | 0.14% |

| Maharashtra | 11.09% | 8.50% | 0.86% |

| Madhya Pradesh | 7.10% | 4.19% | 3.15% |

| Odisha | 3.96% | 5.79% | 2.31% |

| Rajasthan | 1.40% | 0.07% | 0.31% |

| Dadra & Nagar Haveli | 0.66% | 0.24% | 0.09% |

| Jharkhand | 0.48% | - | - |

| Delhi | 0.07% | - | - |

| West Bengal | 0.00% | 0.00% | - |

| Total raw material purchases | 100.00% | 100.00% | 100.00% |

The prices of our raw materials are based on, or linked to, the global pricing of such raw materials and components. Volatility in commodity prices can significantly affect our raw material costs. While we endeavour to pass on all raw material price increases to our customers, we may not be able to compensate for or pass on our increased costs to our customers in all cases. If we are not able to compensate for or pass on our increased raw materials costs to our customers, such price increases could have a material adverse impact on our result of operations, financial condition and cash flows. Our raw materials expenditures are denominated in Indian rupees and we do not have raw material expenses in foreign currencies. However, we expect that after our backward integration raw materials may be imported exposing us to foreign currency risk in the future.

We usually do not enter long-term supply contracts with our raw material suppliers, and typically source raw materials on a purchase order basis. The terms and conditions of these purchase orders contain provisions related to the supplier’s product quantity, pricing, payment and delivery terms. We typically purchase raw materials based on the projected levels of sales, actual sales orders on hand, and the anticipated production requirements, taking into consideration any expected fluctuation in raw material prices and lead time. The prices of our raw materials are based on, or linked to, the international prices of such raw material and the variations are typically passed on to the customer.

Coal and Gas

Carbon from coal is a major reducing agent and heat source to convert scrap to billets and in the production of TMT Bars. After our new electric induction furnace is operational that we are installing as part of our backward integration, we expect that our coal consumption will be substantially reduced.

Carbon from coal is a major reducing agent and heat source to convert scrap to billets and in the production of TMT Bars. In respect of coal, we sourced our requirements from two (2) suppliers in Fiscal 2024, six (6) suppliers in Fiscal 2023 and thirteen (13) suppliers in Fiscal 2022. Natural gas is used to cut billets during production. We source our natural gas locally from third parties in the State of Gujarat.

The prices of our coal and gas are linked to the international prices and the variations increase our costs of manufacturing.

The prices of our coal and gas are linked to the national and international prices and the variations increase our costs of manufacturing.

The table below sets forth our expenses for coal and gas consumption for the periods indicated:

| Particulars | Fiscal 2024 | Fiscal 2023 | Fiscal 2022 |

|---|---|---|---|

| ₹ lacs | ₹ lacs | ₹ lacs | |

| Coal and gas consumption | 1,183.20 | 1,740.73 | 859.41 |

Power, Fuel, Oxygen, LPG, Water

For our production of TMT Bars and our production of billets from scrap, we use oxygen, LPG, water, power and fuel to run our furnaces and equipment and in the production processes itself. Our power requirements are sourced through the local state power grid. We also consume a of water for our operations, which is sourced locally. We also procure natural gas, LPG and oxygen from local suppliers in Gujarat.

The table below sets forth our expenses for (i) oxygen and LPG, (ii) water and (iii) power and fuel, for the periods indicated:

| Particulars | Fiscal 2024 | Fiscal 2023 | Fiscal 2022 |

|---|---|---|---|

| ₹ lacs | ₹ lacs | ₹ lacs | |

| Oxygen and LPG expenses | 9.37 | 7.72 | 9.41 |

| Water charges | 0.23 | 2.26 | 1.03 |

| Power and fuel expenses | 1,483.28 | 1,396.53 | 606.31 |

Our power and fuel expenses have increased significantly in recent years due primarily to an increase in electricity prices, and further increases in power and fuel expenses may impact our margins if we are not able to pass these price increases to our customers. We expect our power requirements and power expenses to increase significantly due to the installation of our thirty-ton electric induction furnace as part of our backward integration project.

As part of our strategy, we are planning to set up a 15 MW solar power plant near our manufacturing facility for our captive consumption to reduce our power expenses.

Logistics

We transport our finished equipment by road. We generally sell our TMT Bars on a F.O.R. basis, which means to our customer’s door. In addition, we pay for transportation costs in relation to the delivery of raw materials and other inputs to our manufacturing facility. Our manufacturing facilities (including our new leased facility) and over 98% of our customers in Fiscal 2024 were located in Gujarat.

We do not own any vehicles for the transportation of our products but use a dedicated fleet of over 50 trucks provided by a third party transportation and logistics provider for delivery of our products. We also use third party transportation providers for the delivery of raw materials. We do not have any contractual arrangements with any such third-party transportation and logistics providers, and they could stop providing transportation at any time. Any disruption in services by such third-party transportation provider could impact our manufacturing operations Disruptions of logistics could impair our ability to procure raw materials and/or deliver our products on time. We keep our inventory of products and raw materials at our manufacturing facility.

The following table sets forth our freight and cartage on sales charges and such charges as a percentage of total expenses in the periods indicated.

| Particulars | Fiscal 2024 | Fiscal 2023 | Fiscal 2022 |

|---|---|---|---|

| ₹ lacs | ₹ lacs | ₹ lacs | |

| Freight and cartage on sales | 1,502.20 | 1,350.54 | 719.51 |

Inventory Management

We maintain high inventory levels of raw material requirements for the manufacture of our TMT Bars and, prior to our backward integration, iron billets used to produce the TMT Bars. The inventory of finished products is typically based on a combination of confirmed and expected orders, as well as a projected annual forecast from customers. Our working capital management is done considering all these factors.

The table below sets forth our inventory, average inventory and inventory turnover ratio as at, or for the periods, indicated:

| Particulars | Fiscal 2024 | Fiscal 2023 | Fiscal 2022 |

|---|---|---|---|

| Inventories | 10,936.62 | 10,586.34 | 4,343.12 |

| Inventory turnover ratio | 8.11 | 11.82 | (31.35) |

Health, Safety and Environment

We are subject to national, regional and state laws and government regulations in India relating to safety, health and environmental protection. These laws and regulations impose controls on air and water discharge, noise levels, storage handling, employee exposure to hazardous substances and other aspects of our manufacturing operations. Further, our products, including the process of manufacture, storage and distribution of such products, are subject to numerous laws and regulations in relation to quality, safety and health.

As of March 31, 2024, our manufacturing facilities were certified ISO 45001:2018 for occupational health and safety management system standards and ISO 14001:2015 for environmental management system standards.

Health and employee safety

We are committed to maintaining high standards of workplace health and safety, we aim to become a zero-accident organisation. Any mishaps or accidents at our facilities or any emission or leakage from our factory could lead to personal injury, property damage, production loss, adverse publicity and legal claims. We believe that accidents and occupational health hazards can be significantly reduced through a systematic analysis and control of risks and by providing appropriate training to our management and our employees.

We have a safety management system which has been implemented across our manufacturing facilities. We have a safety officer and safety training is carried out jointly with the SKF team every 15 days.

Environment

In addition to creating initiatives to improve workplace employee safety, we also implement initiatives to reduce the environmental impact of our operations.

We are looking to setup a 15 MW solar power plant near our manufacturing facility for our captive consumption to reduce our electricity expenses. For further details, see “Our Strategies –Setting up a 15MW solar plant to reduce power expenses” on page.

Information Technology (IT)

Our IT systems are important to our business. We utilize Tally, an enterprise resource planning software, for basic business functions and use programmable logic controller (PLC) to manage our business processes, sensors and movement of inventory. We do not have an information security and disaster recovery system in place.

Insurance

We believe that our insurance coverage is in accordance with industry custom, including the terms of and the scope of the coverage provided by such insurance. However, our policies are subject to standard limitations, including with respect to the maximum amount that can be claimed. Therefore, insurance might not necessarily cover all losses incurred by us and we cannot provide any assurance that we will not incur losses or suffer claims beyond the limits of, or outside the relevant coverage of, our insurance policies.

Our operations are subject to risks inherent as an TMT Bar and iron billet manufacturer, which include liability for product and/or property damage, malfunctions and failures of manufacturing equipment, fire, explosions, loss-in-transit for our products, accidents, personal injury or death, environmental pollution and natural disasters. We maintain insurance coverage that we consider necessary for our business. We maintain an insurance policy that insures against material damage to buildings, facilities and machinery, furniture, fixtures, fittings, stocks, and machinery breakdown. In addition, we maintain commercial general liability insurance that covers liability in claims for bodily injury (and medical payments), property damage, and personal and accidental injury. We, however, have not taken insurance to protect against all risk and liabilities. For example, we do not have key man insurance, and we do not take insurance for potential product liability claims.

Human Resources

We place importance on developing our human resources. As of March 31, 2024, our workforce comprised employees, and we utilised the services of contract labourers. Combinations of full-time employees and contract personnel gives us flexibility to run our business efficiently.

Our work force is a critical factor in maintaining quality, productivity and safety, which strengthens our competitive position. We are committed to provide safe and healthy working conditions. We currently do not have any registered trade unions. The average tenure across all our employees is approximately years.

We offer formal and informal training as well as on-the-job learning. Our training is carried out at our manufacturing facility to help turn unskilled labour into semi-skilled labour, and semi-skilled labour into skilled labour, thus increasing productivity.

In addition to compensation that includes salary and allowances, our employees receive statutory benefits (including employees provident fund, pension, retirement and gratuity benefits, workman’s compensation, maternity and other benefits, as applicable) and are covered by group personnel accident.

Competition

Although the TMT Bars industry provides for significant entry barriers, competition in our business is based on pricing, extent and efficiency of the distribution network, relationships with customers particularly in the construction industry, product quality, and compliance with government regulation including environmental regulation. . We face pricing pressures from companies, principally subsidiaries of large national steel companies and Indian TMT Bar companies that are able to produce TMT Bars at competitive costs and consequently, may supply their products at cheaper prices. Accordingly, to remain competitive in our market, our Company must continuously strive to reduce our operating costs and improve our operating efficiencies. Further, our Company believes that our well recognized brands also help us in competing effectively in the TMT Bars.

Intellectual Property Rights

We have a retail licence agreement with Kamdhenu Limited which allows us to market our TMT Bars exclusively in Gujarat (except Kutch and Saurashtra) under the brand “Kamdhenu NXT”. In Fiscal 2024, Fiscal 2023 and Fiscal 2022, we paid Kamdhenu Limited their royalty from our total revenue from operation for the same respective periods. Our retail license agreement is terminable by Kamdhenu Limited by giving one-month advance notice to us without any cost or reason.

We have acquired and developed and continue to acquire and develop knowledge and expertise, or know-how, and trade secrets in our businesses, including know-how and trade secrets related to proprietary technologies and patents, trademarks, know-how and trade secrets. Our know-how and trade secrets in our businesses may not be patentable, however, they are valuable in that they enhance our ability to provide high-quality products to our customers.We have a trademark application pending for our corporate logo. We also rely on a combination of trade secret and contractual restrictions to protect our intellectual property. If we are unable to protect our intellectual property rights, our business, results of operations and financial condition may be adversely affected.

Properties

Our registered and corporate office is located at Survey No. 214 Water Tank, , Bhayla Village, Bhayla, Ahmedabad, Gujarat 382240, India. Further, our Company runs its operations from its manufacturing facility which are located at the same address. The land on which our registered office and manufacturing facility are located are owned by our Company.

We have entered a factory lease agreement, with Hans Industries Private Limited, dated June 4, 2024, under which we are leasing a facility in Bhavnagar, Gujarat with an approximate installed capacity of 5,500 MT of pipe per month. The term of the lease is five years and expires on June 30, 2029,with an option to renew the agreement after every 11 months and 29 days.

Legal Proceedings

For details on any outstanding litigation against our Company, our Directors and our Promoters. Please check on about us.

Corporate Social Responsibilities

As per provision of Section 135 of the Companies Act, 2013, we are required to spend at least 2% of the average profits of the preceding three fiscal years towards Corporate Social Responsibility (“CSR”). Accordingly, our Board of Directors has constituted a CSR Committee for carrying out the CSR activities.

In Fiscal 2024, we contributed to the UMIYA Education Charitable Trust and in Fiscal 2023 we contributed to the Arya Foundation for the improvement of women’s life style and children’s development and education.

The table below sets forth the amounts we spent on CSR for periods indicated.

| Particular | Fiscal 2024 | Fiscal 2023 | Fiscal 2022 |

|---|---|---|---|

| ₹ lacs | ₹ lacs | ₹ lacs | |

| CSR Expenses | 10.45 | 7.01 | 0.00 |